Value #02

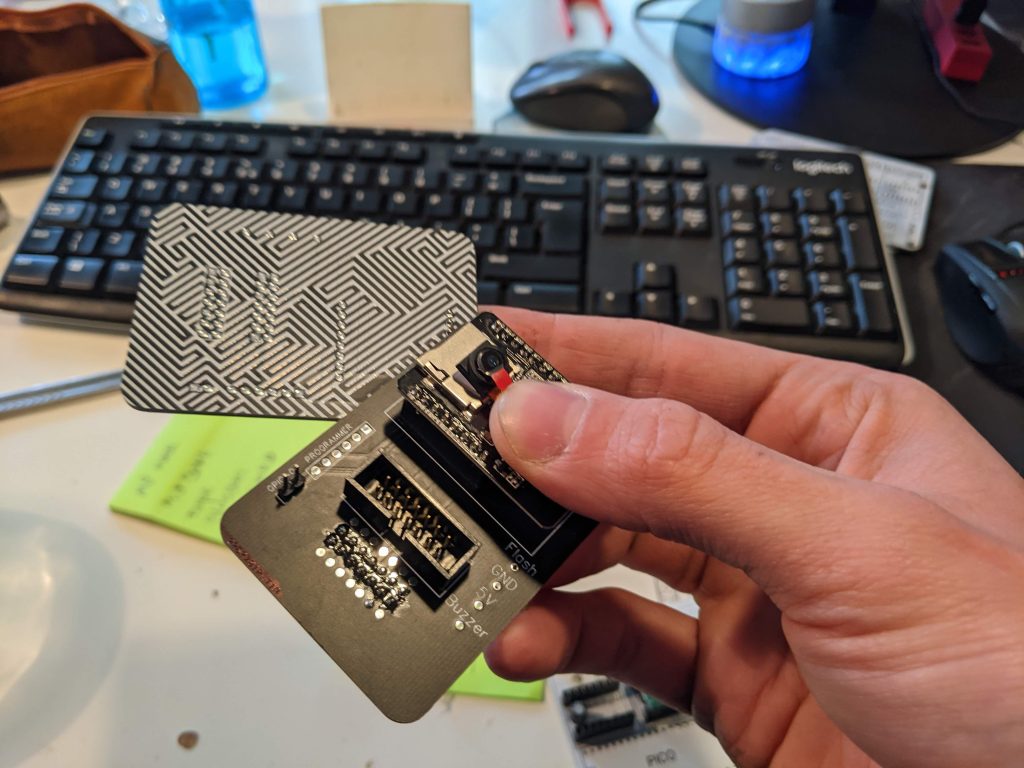

I make things.

In the real world, theory often meets reality with unexpected challenges. Products don’t always fit as planned, and mechanisms don’t always work seamlessly. That’s why I believe in the power of hands-on creation. By crafting prototypes and building products from the ground up, I transform assumptions into facts.

It’s not just about proving theories; it’s about showing that we can actually make products that work on a big scale. I’m all in for the practical side of things, proving that we can create products that not only look good on paper but can also be made in large quantities.

Expertise

– Problem-solving through Building, I identify and resolve critical design and manufacturing challenges that appear through testing

– Hands-on Fabrication, I have a good understanding of laser cutting, 3D printing, metal and woodworking with a specialty in electronics

– Fast results, I quickly build prototypes due to inhouse tooling, with a streak of 42 project in 36 months

Value #03

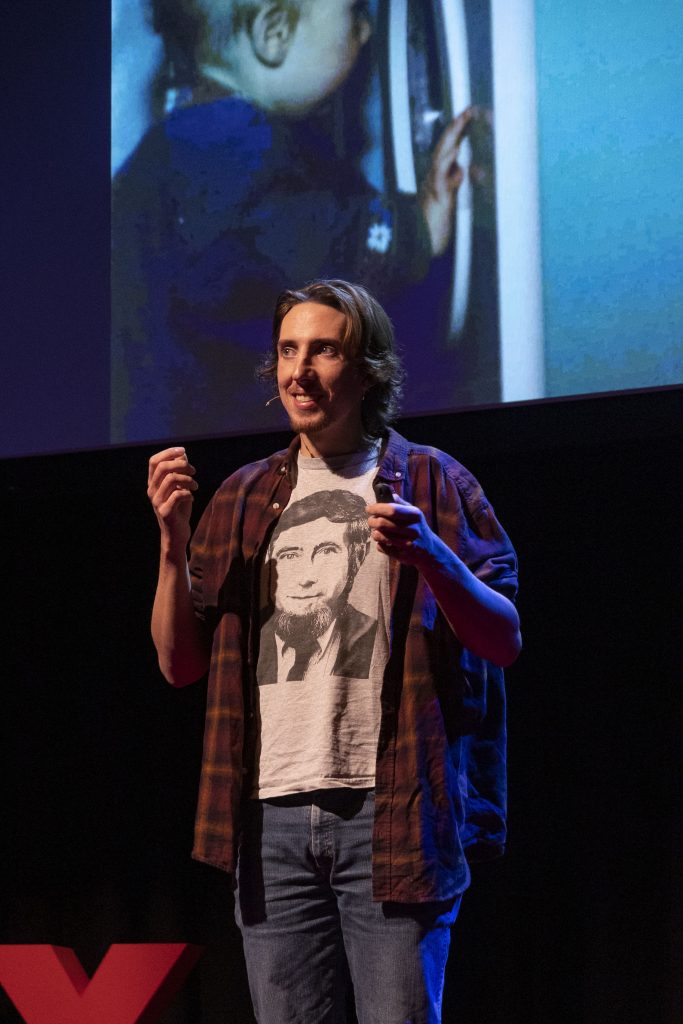

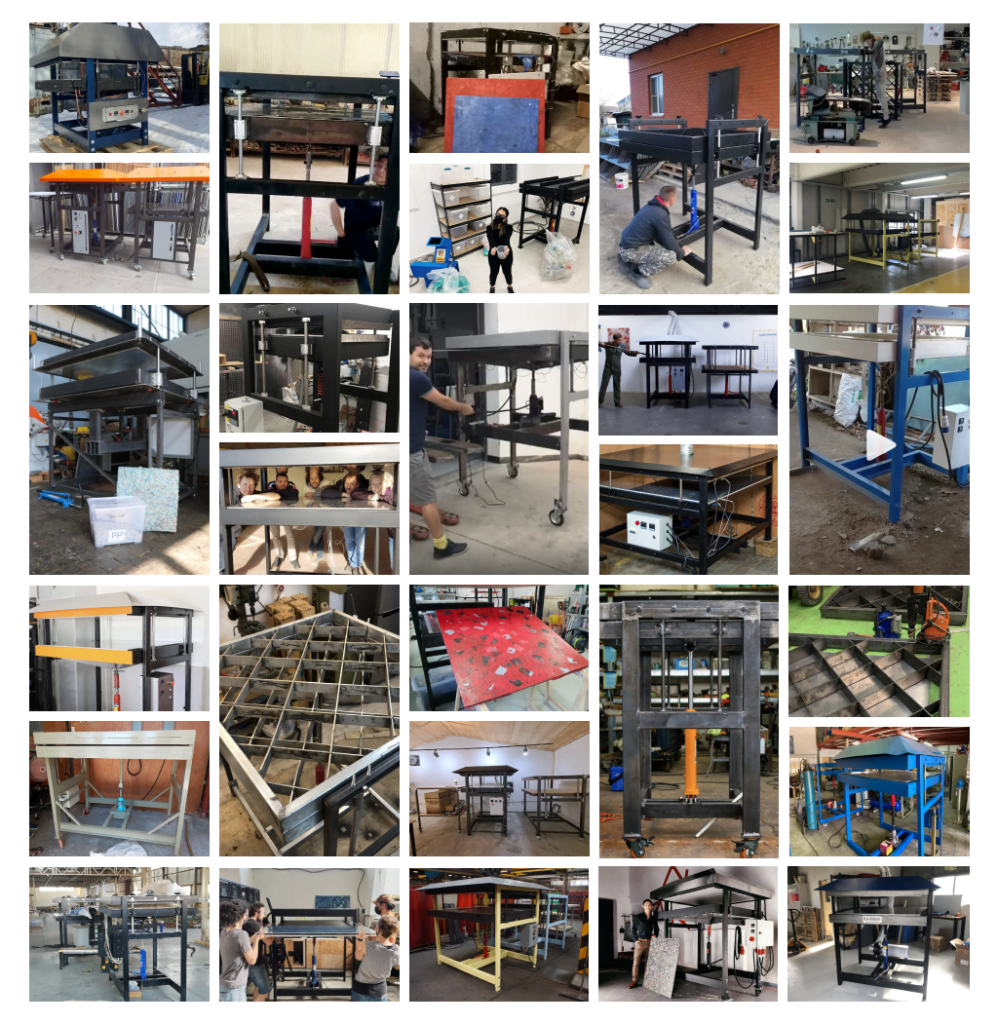

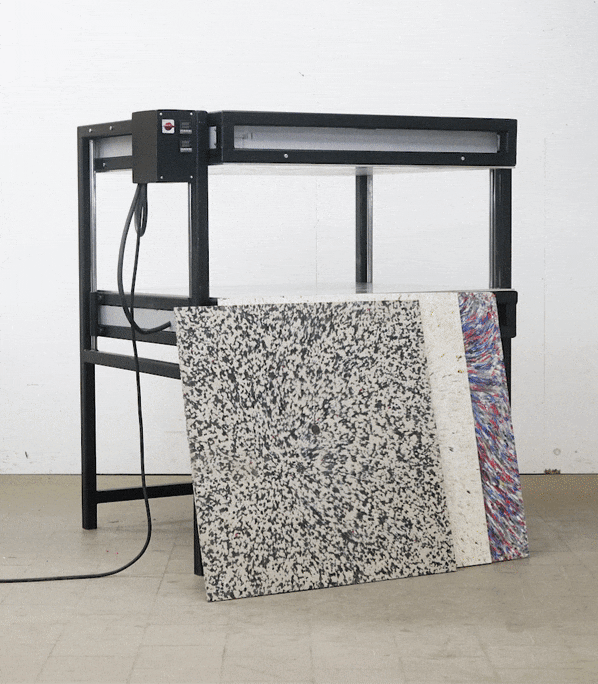

I Fight Waste.

In the Netherlands, we tend to toss things away without much thought – out of sight, out of mind. But when you travel abroad, the issue of single-use plastics hits you hard.

Therefore, I wanted to fight this problem. It is all about getting your hands dirty to tackle the plastic problem from the ground up. Figure out what machines people need for recycling, research what resources each community has, and find ways to bring folks together. Giving people the necessary tools to start plastic recycling themselves. And the best part? It’s all free and open-source – because being part of the solution shouldn’t cost a thing.

Expertise

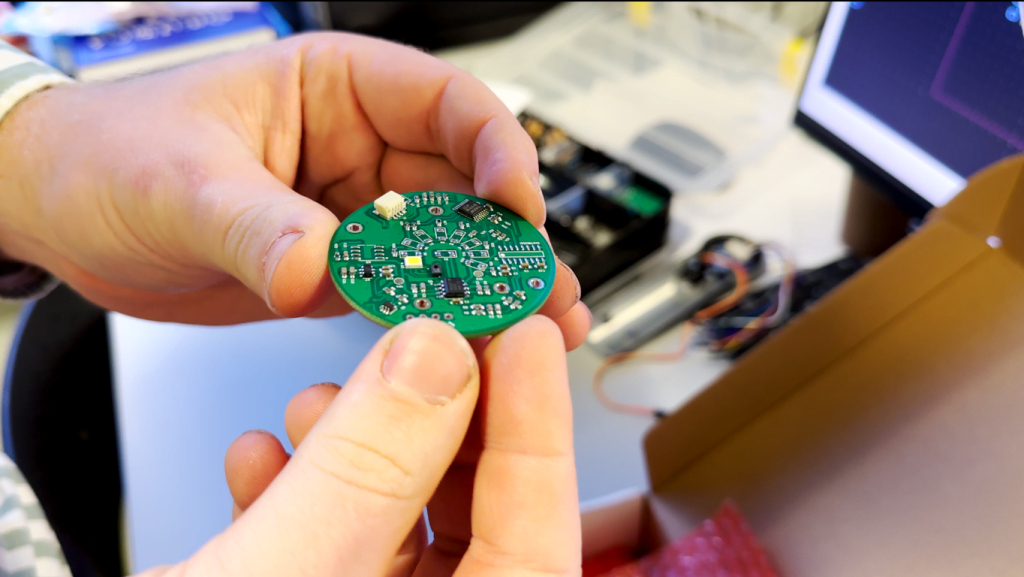

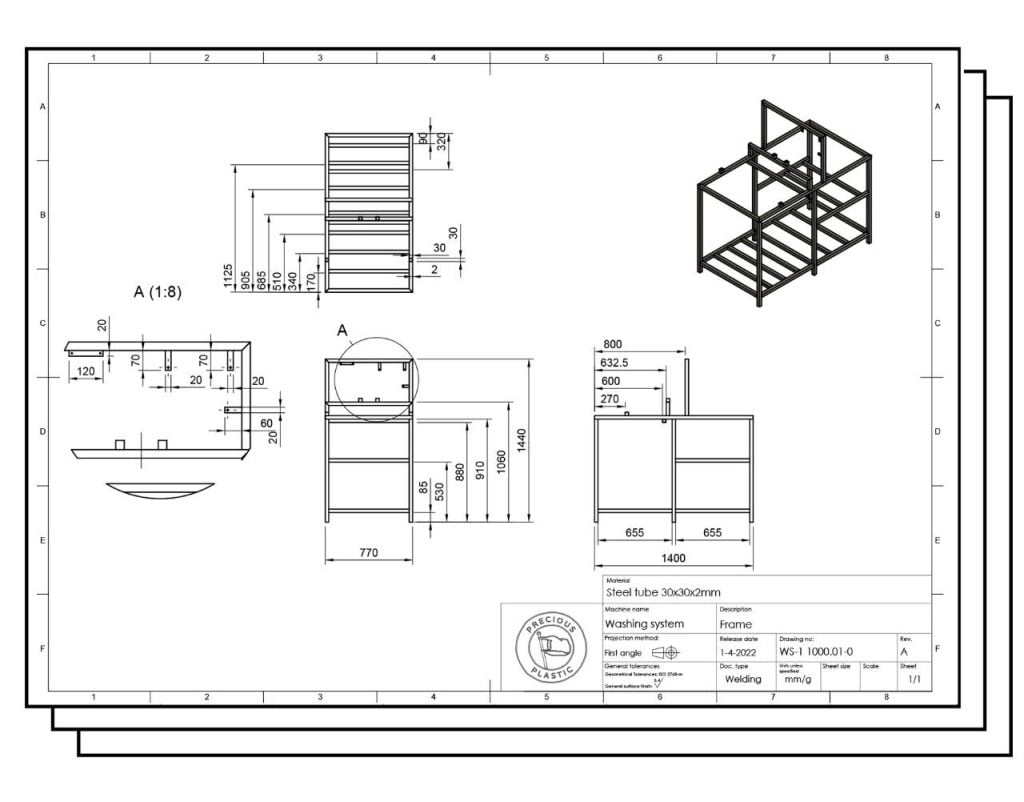

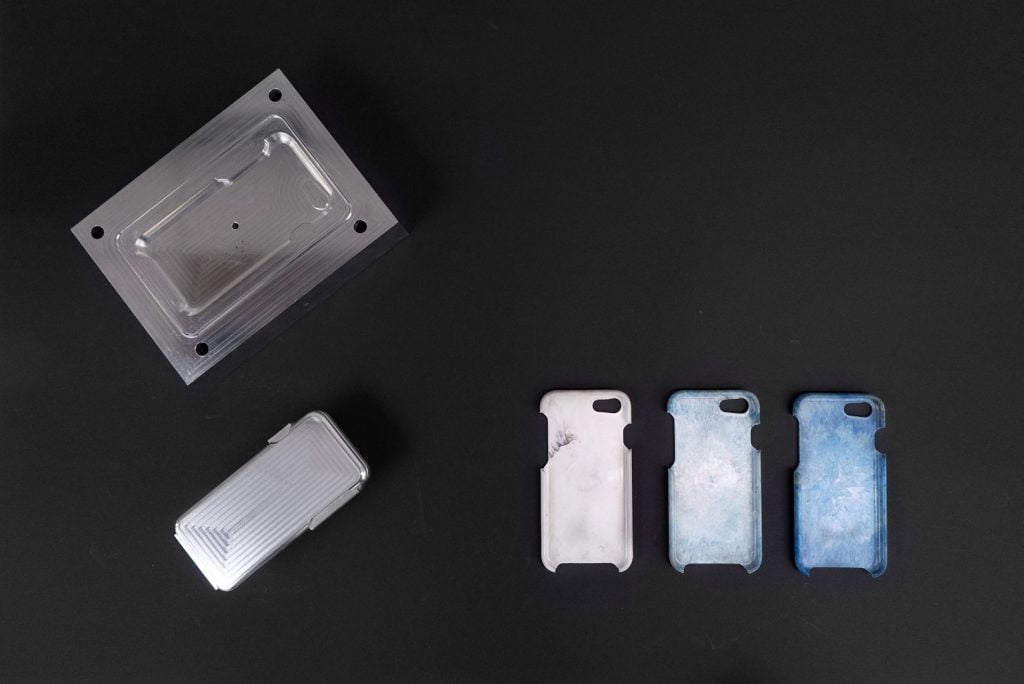

– Expert in plastic recycling, I have been in the plastic recycling business for 5 years, developing new tools like the sheetpress, the washing system, and the Plastic Scanner

– Setting up recycling workspaces, From Algeria to the Himalayas I helped to set up recycling workspaces with knowledge about machines and training for the community

– Local circular knowledge, I can quickly scan a local environment and propose solutions for improved circularity and unique new possibilities

Value #04

I love electronics.

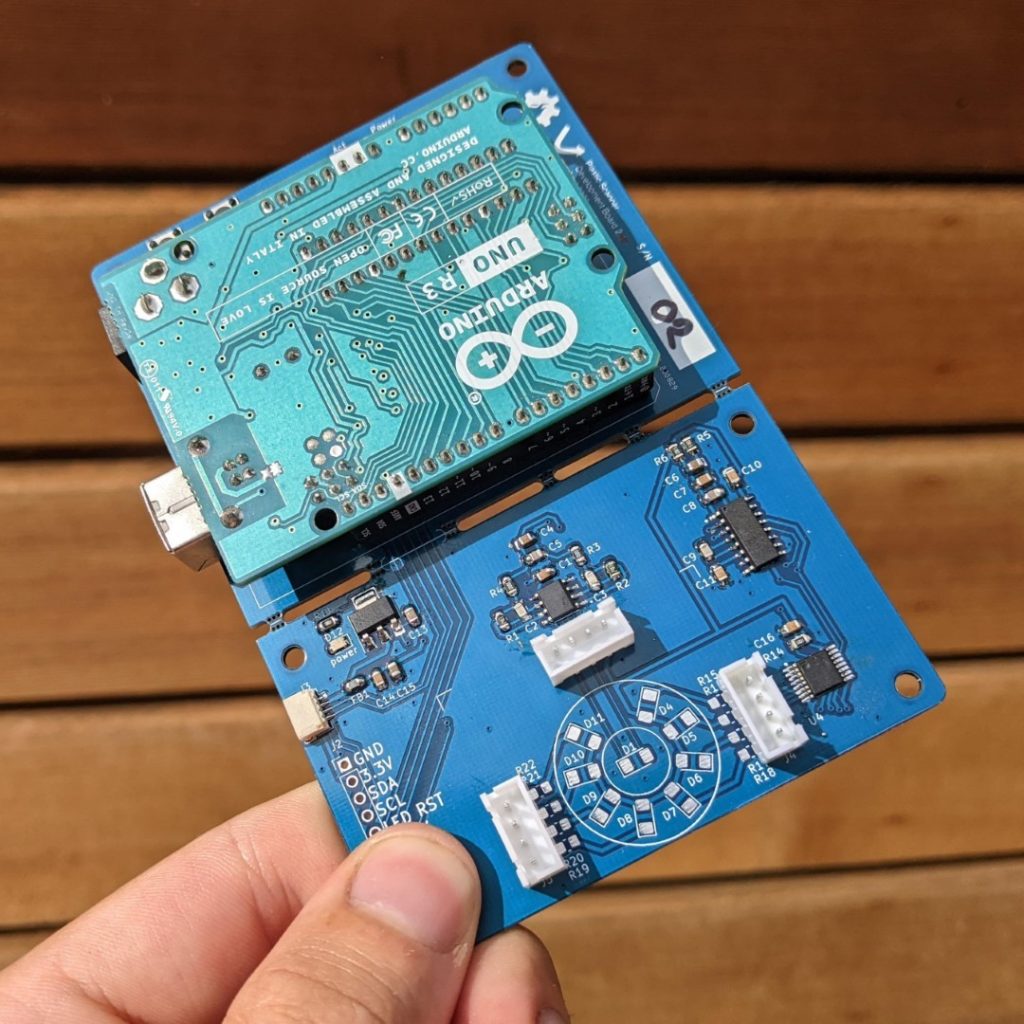

I’m fascinated by how electronics are changing the game in product design, bringing interactions we couldn’t even dream of a few years back. Exploring this new dimension, I dive into researching how these advancements can bring meaningful interactions with users.

Moreover, I enjoy crafting custom embedded systems for clients to meet their specific needs. It’s not just about keeping up with technology; it’s about harnessing it to create unique, tailored experiences.

Expertise

– Tailored Electronics Solutions, I build custom embedded solutions for any possible project

– Custom PCB Design, I design and create custom printed circuit boards (PCBs) for various electronic applications.

– SMD skills, I feel comfortable designing, testing and using small SMD components with either inhouse hot air or reflow work